|

The Hawthorn Farm Athletic Club in Northeast Hillsboro.

|

Four sets of double-entry glass edged entry doors. These are also sometimes known as Herculite Doors or frameless glass doors.

|

Due to some apparent settling of the building, the openings or both, the glass-edged doors are rubbing on the aluminum header-jambs.

Nobody probably needs to be told that glass hitting metal is not a good thing.

|

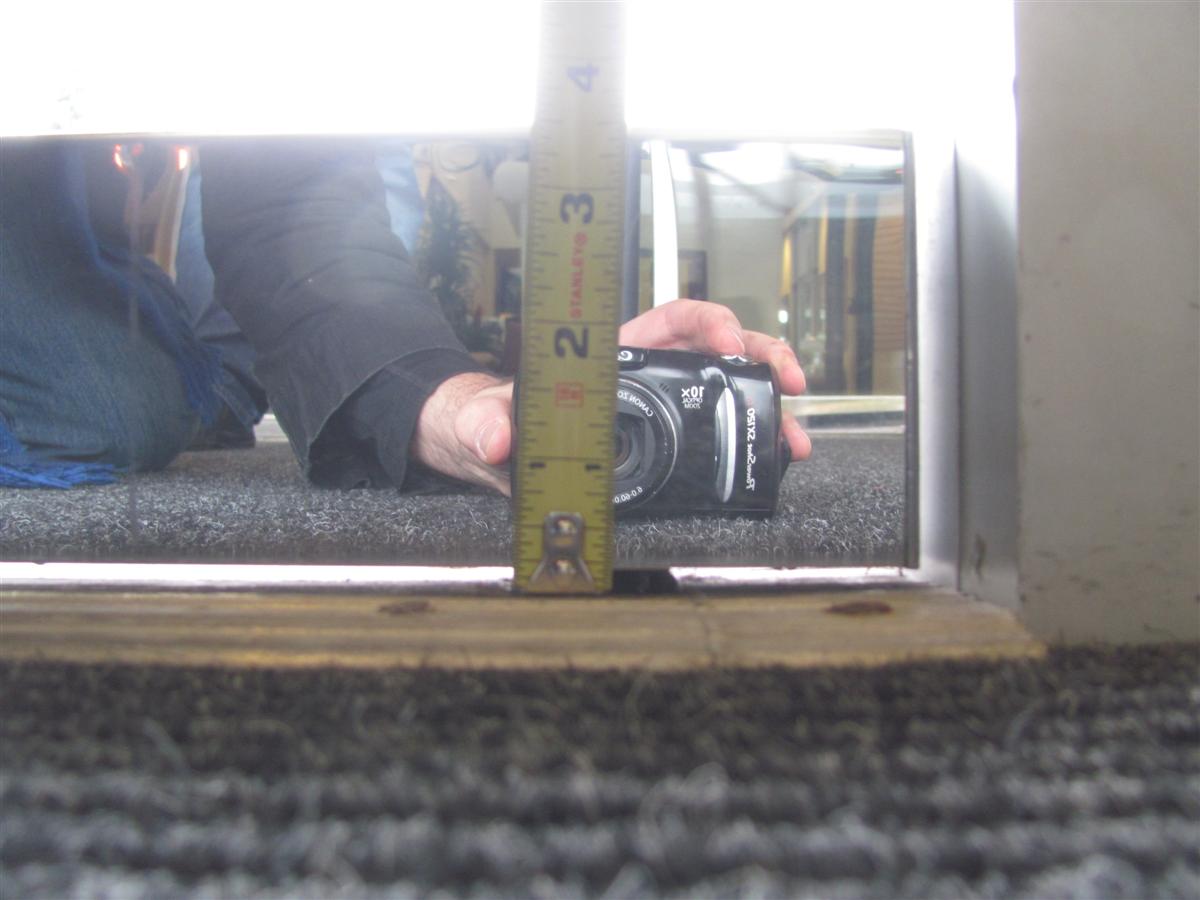

As this photo shows, the spacing between the bottoms of the doors and the aluminum thresholds is quite minimal. If the exact context of this photo is a little hard to resolve, it’s probably the bright-chrome bottom-rail of the door reflecting the camera in my hand as I take the photo.

|

So gaining some room for the top of the doors is not going to be a cakewalk, which may be why our client told us that other door companies told them they would have to replace their doors. If you enlarge the photos by clicking on them, you may be able to make out better what we trying to show in these photos.

|

By adjusting the pivot-hinge brackets in the bottoms of the doors we may be able to gain from a sixteenth to an eighth of an inch before we risk hitting the thresholds.

|

Tolerances are tight. Raising the bottom bracket into the bottom of the door to lower the doors in the jamb…

|

…creates concern about the bottom-bracket fasteners hitting the glass, so the screws are modified with a grinder.

|

We also sought a means by which to raise the header-jambs by modifying the bracketing that holds the header-jambs to the mull-posts.

|