|

A solarium or, as some would call it, a Sunroom on the back of a house in Tigard. Our client wants to put his house on the market, but…

|

…thinks it best if the radiused insulated glass units that have failed are replaced before allowing prospective buyers in to view the home.

|

So we hatched a plan to try something we had never before tried. Our plan involved removing the original “bent-glass,” as it’s called in…

|

…the industry, and temporarily securing the solarium from the elements. We then took the three insulated units back to our…

|

…warehouse, whereupon we disassembled the insulated units down to individual panes of glass and took to trying to remove the…

|

…oxidized consequence of the seal-failure of insulated glass. Frankly, I am not certain what causes the oxidation upon the glass that sometimes happens when moisture is allowed to get in-between the panes. Perhaps a chemical reaction to the aluminum spacer-bars or perhaps a gassing-off that occurs when the desiccant inside the spacer-bars gets wet. We tried everything we could think of or find advertised for oxidation removal.

|

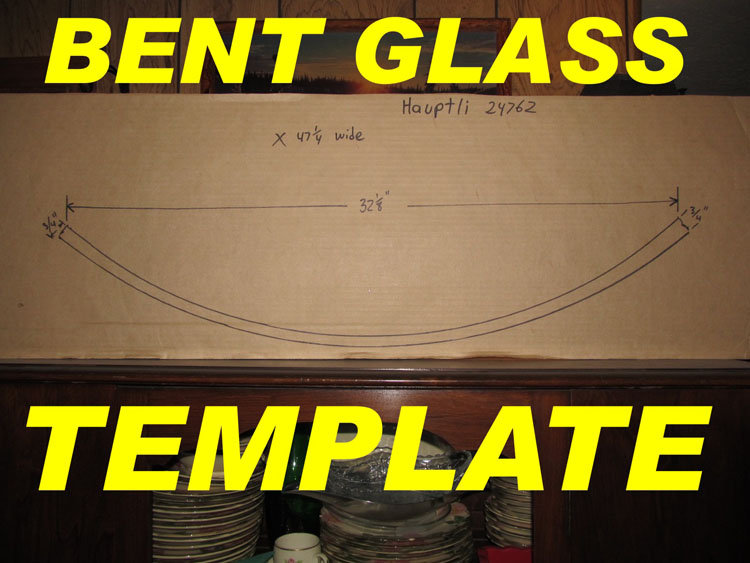

In the previous photo, our technician Brandon is applying Jewelers ruse with a buffing wheel on the end of a die-grinder, which was the last of about a dozen products that were advertised or recommended by folks we know in the industry as being good for oxidation removal. I can now tell you from experience that nothing even remotely worked. So a template was made and an order was placed with California Glass Bending.

|

Thousands of dollars later, we had three brand new insulated glass units to install back into our client’s solarium structure. No, we did not pass our “research and development” costs onto our client. They were significant to say the least, but in my experience, most valuable educations are.

|

I like to think that our desire to learn and to grow in our field of expertise is among several characteristics promoted in our company that tend to set us apart from some of, if not most of the competition.

|

Although there is no way for us to know for certain, we do seem to enjoy an ever increasing amount of favorable feedback from our clients. If something can be done in the field of door & windows, we likely do it. And then some. Water leak remediation is but one example of our problem-solving inclinations opening up ever increasing markets for us.

|

|

|